Pozzetta Microclean Services

Pozzetta provides assured, accredited, and immaculate microclean services to global industry leaders of the critical device industry. Our processes ensure that your critical devices remain free of contaminants by meeting specified particles per cubic meter, ultimately resulting in a higher fab yield and optimized production.

Contact Us

Our world-class microclean facility upholds our unique position within the industry due to a few key distinctions:

- 1,000 ft² of Class 1000 cleanroom

- Two Class 1 mini cleanroom environments

- Class 1 packaging environment

- 8,000 ft² warehouse space

- Benchmark ultrasonic sensing

- 18 megohm de-ionized water

- 0.05 micron filtration

Reduce particles

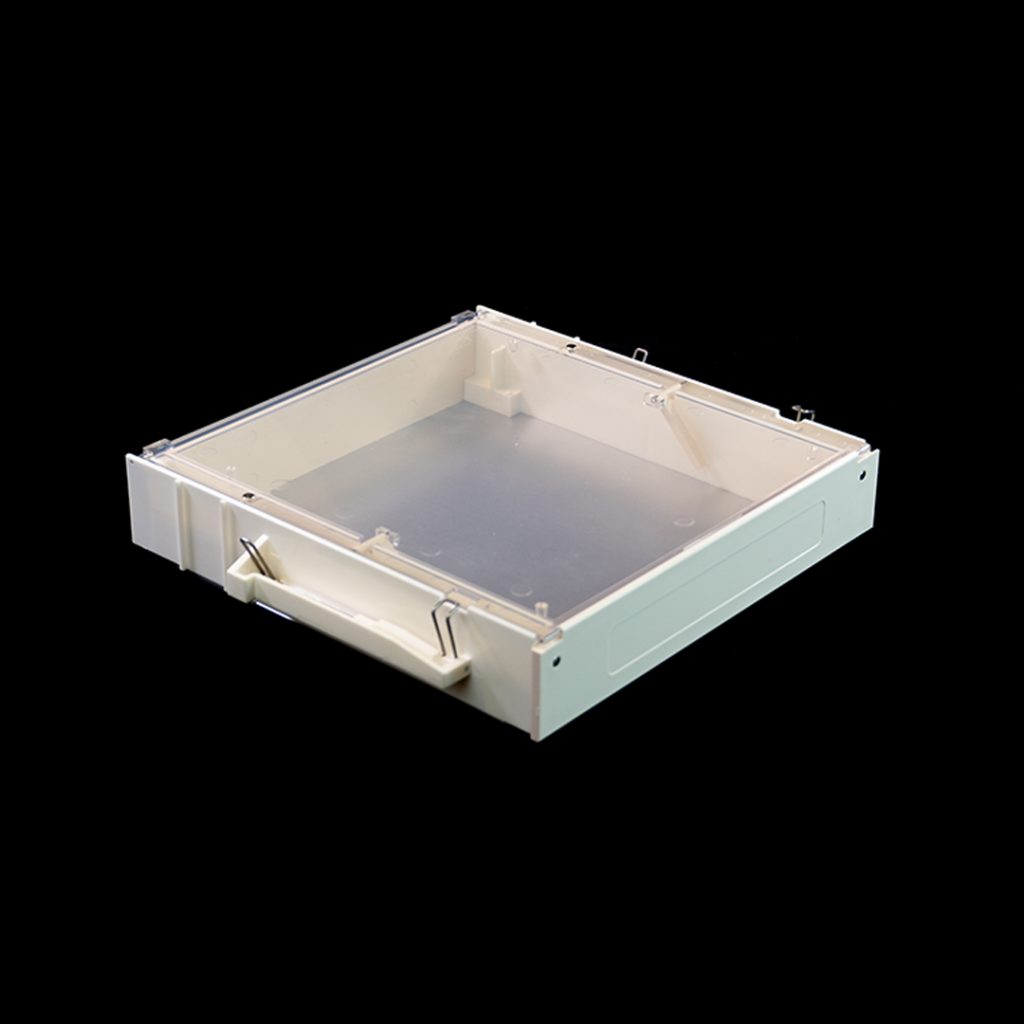

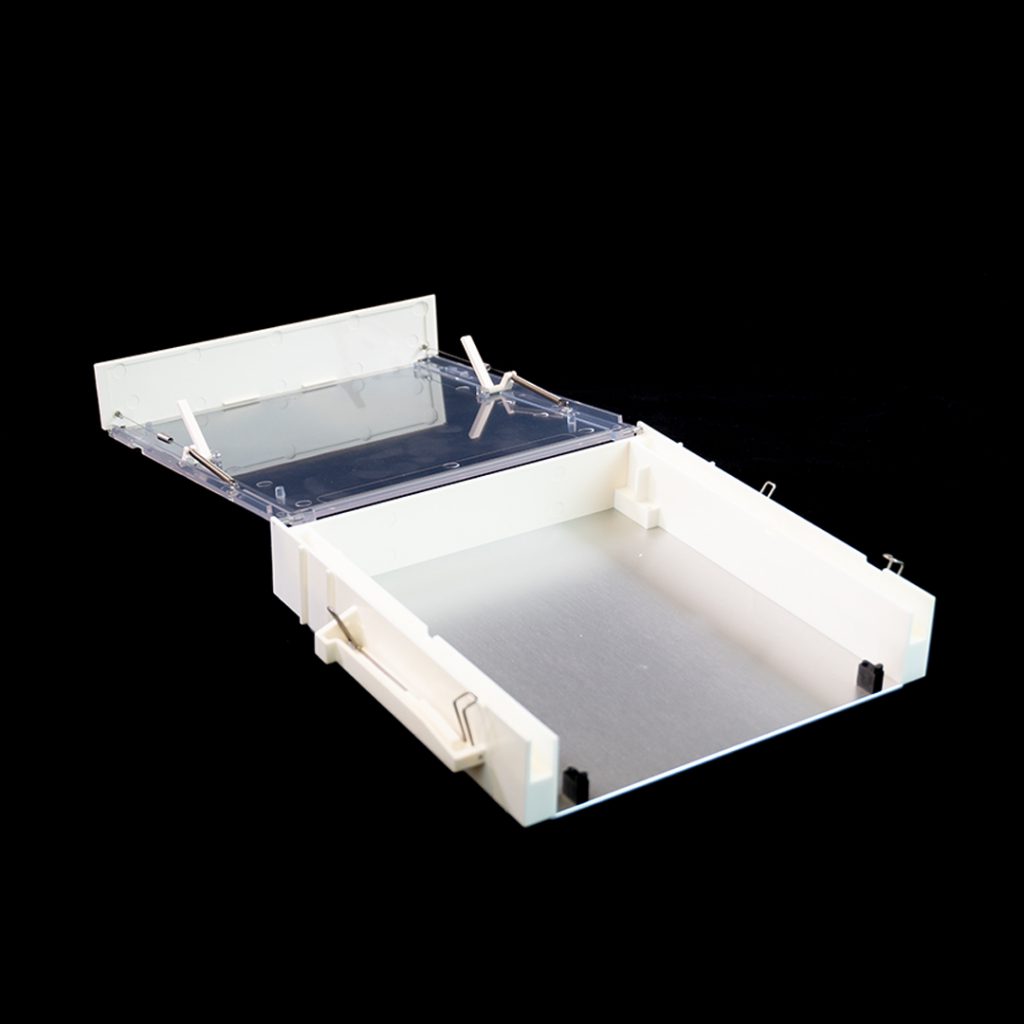

Pozzetta’s expertly-trained microclean crew holds an in-depth intellect into the world of particle reduction for semiconductor device & microelectronics containers. Our systematic microclean process ensures that your critical devices are properly purified and cleansed, removing any possible contaminants that may increase your particles per cubic inch. By using our in-house pressurized filtration system that pumps deionized water into our class 6 cleanroom, your critical device containers are absolved of contaminants through the use of our industry-grade washing system.

Increase fab yield

When Pozzetta’s microclean specialists are tasked with purifying your critical devices, your company will ultimately experience an uptick in production efficiency and overall success rate. By cleansing your carriers of contaminants and reducing your particles per cubic inch, Pozzetta microclean services increase your wafer fabrication yield, eliminating wasted time and expenses. If your company’s production yield leaves much to be desired, enlist Pozzetta for renowned, certified microclean services at our state-of-the-art cleanroom.

Uphold integrity

Here at Pozzetta, our specialties in the critical device industry stretch far beyond microclean services into the world of molding, manufacturing, packaging, and optimization. As full-service experts in the world of semiconductor device handling, our microclean team possesses an unrivaled understanding of the unique complexities and delicacies of your critical devices. With this intuitive knowledge, Pozzetta’s microclean services are guaranteed to preserve device integrity, function, and legibility for future adoption and adaptability.