Clean

Although a universal pillow cushioning concept available, Nefab can design special inserts for the C2C cube. This customized option ensures maximum cleanliness and purity when handling your critical devices.

PL1400WS-2300

PL1400WS-2300

PL1400-20019L

PL1400

PL1400

PL1400

Pozzetta’s product designers aim to create a new product design that modernizes and simplifies the way your critical device packaging looks and feels..

A key element of our 3D printing services is creating critical device packaging designs that interact well with other critical components.

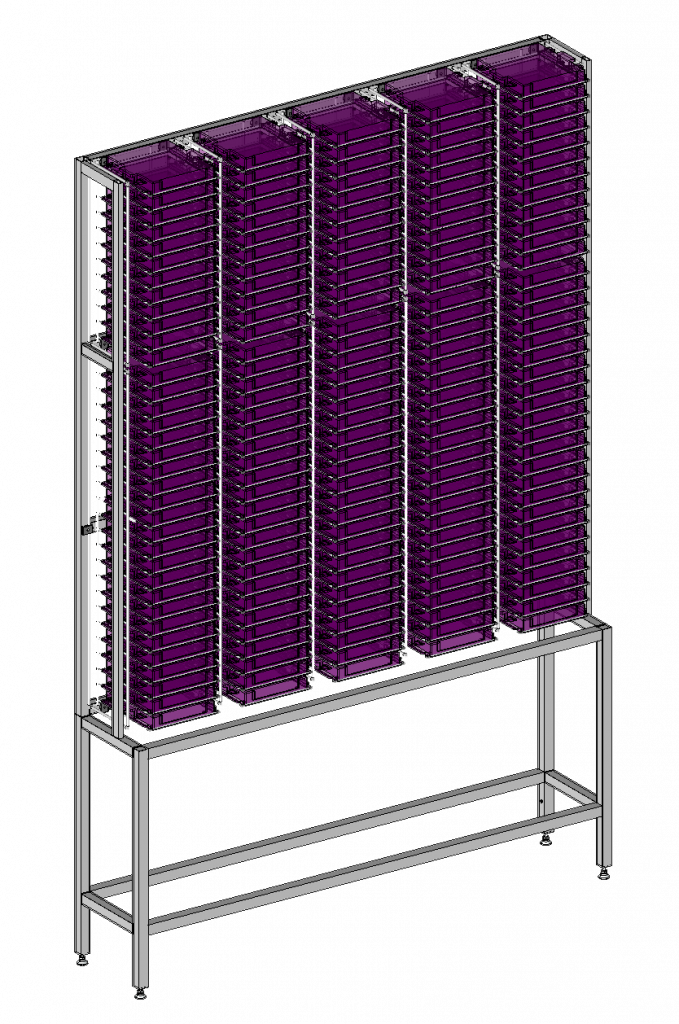

Pozzetta offers customized reticle storage components that perfectly preserve your critical devices while optimizing available facility space.

I have helped customers optimize cleanroom storage space with racks custom designed to organize and hold SMIF pods. Is this something that resonates with you?

Account Executive

Pozzetta’s critical device tracking system keeps your team one step ahead of production, ensuring no ideas or changes get lost in the pipeline while keeping you focused on your important work.

Pozzetta’s tracking & software systems enable you to track the status of your WIP, following along with every stop of the critical device manufacturing, fabrication, and packaging process.

Our WIP database allows your team to focus on the task at hand without getting caught up in the minute details of production, freeing up valuable time spent resolving assembly & manufacturing issues.

Our spacious injection molding department allows our expert team to manufacturecritical device packaging with ease and accessibility, while upholding stringent ISO standards.

Our 30 injection molding presses assure fluidity and rapid succession of your new critical device carriers and other products, with open space to balance multiple projects at once.

This wide range of press weight provides a versatile breadth of options for your business to create original injection molds in a variety of sizes and uses.

Our expanded cleanroom facilities allow our team to tackle medical and industrial client projects with ease and timeliness, ensuring your critical devices are always in safe hands.

Pozzetta’s spacious headquarters enable your business to grow with us, giving you the freedom to evolve your production and optimize your yield with our expert crew on your side.

As experts of the critical device world, we understand the unique challenges you may face when developing, transporting, and packaging your valuable devices. In order to simplify the process and free up time spent figuring out the minute details, allow Pozzetta to tackle your packaging and engineering challenges with finesse and fluidity.

Pozzetta’s packaging and engineering solutions ensure your critical devices are always preserved and protected through various transports, checkpoints, and assembly lines.

Pozzetta’s microclean experts ensure that our facility adheres to the most rigorous of cleanroom standards set by ISO, keeping a clean and organized work space at all times.

Our original packaging and engineering solutions are developed with your critical device designs in mind, with one-of-a-kind details and upgrades that are unique to you.

The goal of Pozzetta is to simplify the production process for your critical devices, saving valued time lost in packaging confusion and engineering troubleshooting.

Our customized Universal Component Box (UCB) allows a variety of critical device engineers to safely transport their products with ease and versatility. The UCB is made with Purepoly, an inherently dissipative polymer known for its dissipation from static and protection from ESD discharge. Purepoly has a very low concentration of organic and inorganic components, so it is an ideal material choice when outgassing is a concern.

As part of Pozzetta’s continued commitment to protecting photomasks and wafers, we have developed and successfully tested an external packaging solution specifically designed for our shipping and storage boxes.

The MASKSHIELD-1X

The MASKSHIELD14-1X

Setup A consultation

While Pozzetta’s premium solutions serve global industry leaders of semiconductor devices and microelectronics, we take pride in serving low-volume clients and smaller scale projects. With our 3D printing technology, adaptable attitude, and worldly understanding of the semiconductor world and all production, the Pozzetta team eagerly awaits your next low volume project.

Reach out to our team today to learn more about this emerging solution from our integrated critical device team.

Contact usEvery day, our clients rely on Pozzetta to solve their unique scaling, storage, contamination, and efficiency problems that greatly affect the yield of their critical devices. With our industry intellect, hands-on philosophy, and adaptable approach, our team uses ingenuity and creativity to solve these challenges with new-age prototype designs.

Here’s an example of how our prototype development fostered growth and optimization for a valued client of the critical materials world:

I helped my customer by designing a process cassette that doubles as a shipping container. By creating this solution, our customer was able to greatly increase efficiencies and scale production while improving yield.

—Scott Reese, Account Executive

If your products are in need of a fresh perspective, consult the Pozzetta team for unrivaled expertise and commitment.

Contact usThe C2C Cube is specifically designed for packaging and transport of semiconductor manufacturing equipment from one cleanroom directly into another cleanroom.

The C2C cube protects your critical devices from contamination and shocks when transporting between clean rooms. The modularity of the different sizes facilitates multiple configurations of stacking, storing and handling.

Although a universal pillow cushioning concept available, Nefab can design special inserts for the C2C cube. This customized option ensures maximum cleanliness and purity when handling your critical devices.

Special runnels keep the belts in place and secure the box, enabling safe, easy handling (manual or by machine).

Used to return the packaging in clean condition.

Use this on all your product sizes and protect down to 10 G.

To equip the Cube with inner straps or add accessories like special fastening plates.

Lift the box manually, even with a protective PE layer around it.

Each Cube has an integrated RFID tag and cleanable label surface.

The special developed filter regulates the air pressure inside the box in transit without adding a risk for contamination.

The C2C Cube sizes are conform to international logistic standards.The modular concept and special stacking features allow you to ship multiple combinations of boxes safely.